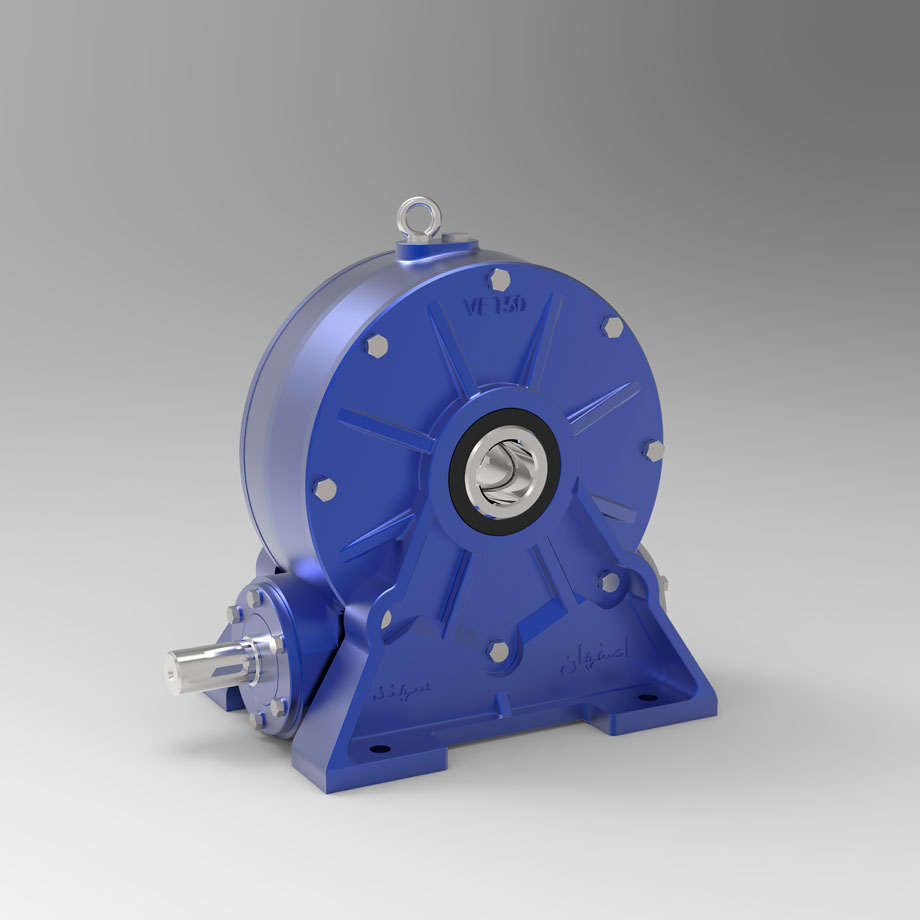

W Series Worm Gearboxes

Worm gearboxes are one of the most well-known and widely used types of industrial gearboxes in the world due to their structure, departure angle, and orthogonality condition. Such gearboxes achieve their kinematic motion by a hardened and stoned steel screw and a bronze worm gear.

The distinctive feature of these gearboxes is the non-reversibility in ratios above 40 and ease of maintenance. Another feature is that they can be used in confined spaces, as well as where the input and output axes cannot be aligned for any reason.

Worm gearboxes can be installed or coupled together in 6 different modes. They are used in different industries, including machinery, construction lifts, blowers and fans, diesel generators, material transfer systems, mines and well drilling, conveyor systems, conveyor belts, compressors, milling machines, bakeries, mills, mixers, stone industries, tiles and ceramics, packaging, food, and other industries.

Advantages and Disadvantages:

Advantages:

- Economical;

- Low noise;

- Very high power capacity;

- Minimum space needed for installation;

- High Safety factor;

- High life span;

- Various installation modes;

- Wide output speed selection range;

- Wide output torque selection range.

Disadvantages:

- They cannot be used at 1500 rpm.

- High operating temperature (due to the gear engagement mechanism);

- Relatively low efficiency (up to 65%).

Technical Specifications

Number of sizes (types): 9

Output torque range: 24 … 1500 Nm

Reduction ratio: 88 … 7100

Power capacity range: 0.12…15 kw

Installation/Assembly (input):

- Input with solid shaft

- Input with e-motor coupling

خروجی :

- HOLLOW SHAFT

Specific (Custom-made) design:

OUTPUT SHAFT

OUTPUT SHAFT ON BOTH SIDE

Torque Range:

| Gearbox Specifications | |

| Maximum Torque | Gearbox Size |

| 88 N.M | VF 49 |

| 190 N.M | VF 62 |

| 440 N.M | VF 86 |

| 830 N.M | VF 110 |

| 1500 N.M | VF 130 |

| 2000 N.M | VF 150 |

| 3600 N.M | VF 185 |

| 5000 N.M | VF 210 |

| 7100 N.M | VF 250 |